| Recent News

Securing Energy Supply While Reducing Emissions

The mining industry is under increasing pressure to ensure reliable power in remote locations, while reducing carbon emissions. With unstable grid access in key regions around the world – from West Africa to South America – and a growing need to integrate renewable energy, operators are looking for solutions that balance energy security and sustainability.

At large-scale mining operations like Fortescue Metal Group’s Iron Bridge Magnetite Project in Western Australia, Bergen Engines’ hybrid power solutions are proving how medium-speed gas engines can keep mining operations running, even when grids fail or renewables fluctuate.

The Energy Challenge: Unstable Grids & Emissions Pressure

Mining is one of the world’s most energy-intensive industries, accounting for 4-7% of global greenhouse gas (GHG) emissions, according to McKinsey & Company.

A large portion of this can come from on-site diesel generators, which historically have been the primary source for powering remote mining operations around the world. For decades, mining companies have relied on these gensets simply due to their ability to operate off grid and provide the reliability for their operations.

However, diesel-based power generation is expensive, inefficient, and highly polluting. According to the International Council on Mining and Metals (ICMM), diesel-powered mines produce up to 50% of their total emissions from fuel use alone. In regions where fuel supply chains are unreliable, diesel costs can soar, increasing operational expenses and leaving power generation unpredictable.

With rising carbon regulations and sustainability mandates, mining companies are under pressure to transition away from diesel. Governments worldwide are also introducing carbon taxes that penalize high-emission power sources, making hybrid energy solutions a smarter long-term investment.

(Photo: FMG)

Bergen’s Solution: Hybrid Power for Maximum Reliability

At Iron Bridge, 15x Bergen B36:45V20 gas gensets (170MW) are integrated with a 150 MW solar PV farm and battery storage, forming a low-emission microgrid. The Bergen gas engines balance solar fluctuations, ensuring constant power even during periods of low sunlight or high demand.

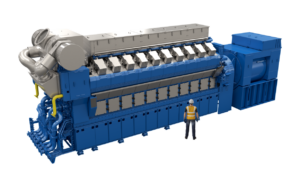

Bergen’s B36:45V20

- Fast response time – Automatically compensates for sudden drops in renewable generation

- Up to 50% efficiency – Cuts fuel consumption and operating costs compared to diesel

- Lower emissions – Helps mining companies reduce CO₂ and comply with regulations

- Scalable and modular – Adaptable for different mining power demands

“Hybrid power systems are the future of mining, but reliability remains critical,” says John Kristian Johnsen, Head of Sales at Bergen Engines. “Our medium-speed gas engines offer an efficient, cost-effective alternative to diesel, ensuring mines can balance renewable energy while maintaining stable, 24/7 power—even in remote locations with no grid access.”

By combining gas power with renewables, mines can reduce reliance on expensive, high-emission diesel while improving power stability—a model that is increasingly relevant for mining operations across Africa, Latin America, and remote regions worldwide.

Illustration of Bergen’s B36:45V20

A Proven Model for the Future

As more mines transition toward hybrid energy solutions, the Iron Bridge project serves as a blueprint for balancing renewables and securing reliable, low-emission power in off-grid locations.

Read the full case study on how Bergen Engines is powering the delivery of 22mtpa of high-grade 67% Fe magnetite concentrate in the Pilbara.

____________________________________________________________________________________________________