| At Sea., Press Releases, Recent News

Bergen, Norway – Bergen Engines, a leader in propulsion solutions for maritime applications, proudly announces the latest milestone in the journey toward decarbonizing the shipping industry. The company’s B33:45 engine has received a formal approval for operation on Hydrotreated Vegetable Oil (HVO), aligning with European standard EN15940 and the U.S. standard ASTM D975 set by the American Society for Testing and Materials (ASTM).

This approval allows for blending of HVO up to 100%, marking a pivotal step toward achieving the EU and IMO’s 2050 vision of net carbon zero shipping.

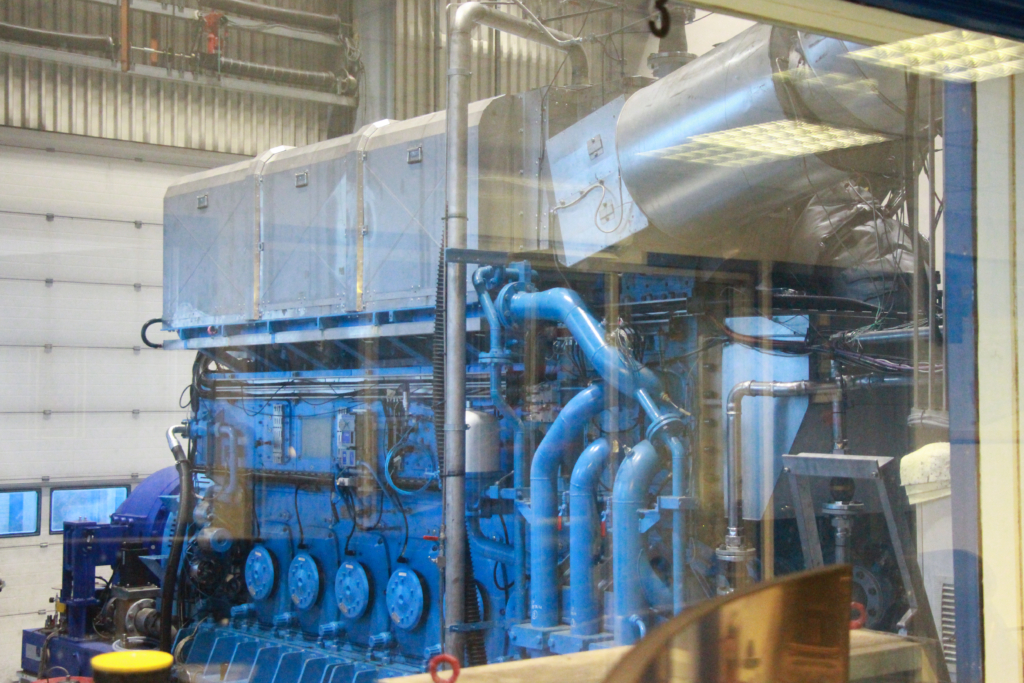

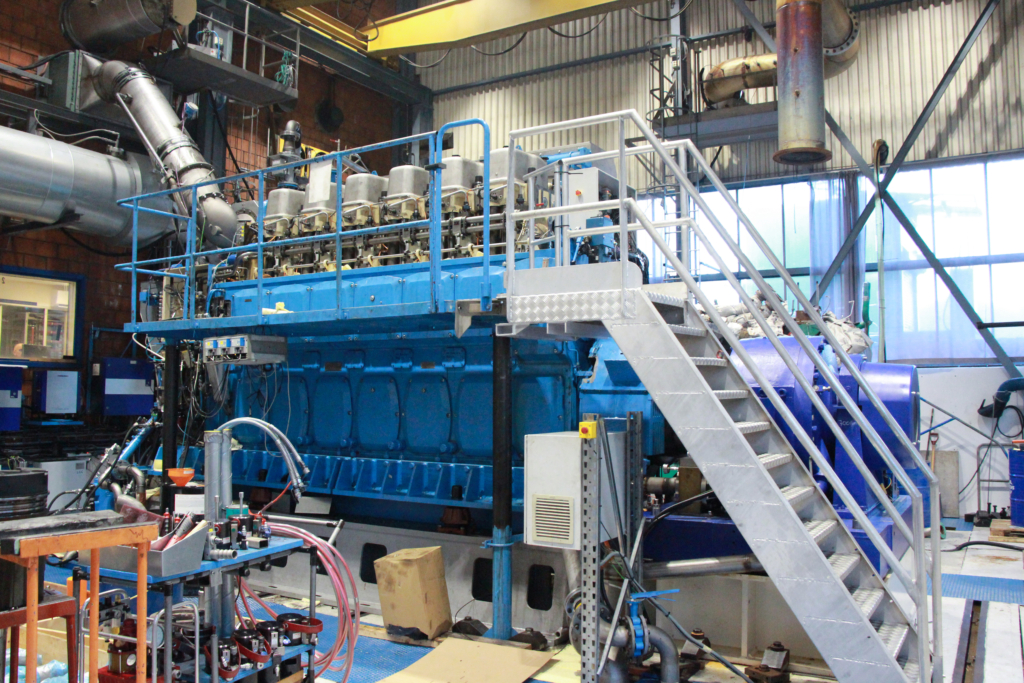

Conducting rigorous full-scale testing at its research facilities in Hordvikneset, north of Bergen, Norway, Bergen Engines’ engineering and R&D teams demonstrated the compatibility and performance of the B33:45 engine with HVO fuel. HVO, also known as “synthetic diesel” or “renewable diesel,” derives from plant or animal oils extracted from meat and fish industry byproducts. Unlike biodiesel, HVO’s organic origin eliminates reliance on agricultural resources and mitigates concerns of deforestation.

With chemical properties similar to traditional diesel fuel, HVO offers a sustainable alternative to the market with nearly identical combustion characteristics. Notably, HVO has several desired properties as minimal aromatic and sulfur content, and a higher cetane value compared to diesel. However, HVO has a lower density than standard diesel oils, leading to a decreased energy density. Its versatility extends to seamless blending with diesel at any ratio, offering a potential reduction in carbon dioxide (CO2) emissions up to 90%, depending on the raw materials used in production.

The Advantages of HVO

In addition to environmental benefits, HVO offers operational advantages for Bergen’s medium-speed engines:

- Reduced lifecycle carbon intensity

- The ability to achieve 100% Maximum Continuous Rating (MCR), comparable to traditional fuels

- Compatibility with existing engine components, oils, and storage systems

- Low-temperature operability and resistance to bacterial growth

- Minimal impact on maintenance intervals

- To maximize the potential of 100% HVO utilization, adjustments may be necessary to maintain engine performance comparable to traditional fuels. However, no specific engine conversion process is required, simplifying the transition for vessel operators.

Collaboration

Bergen Engines emphasizes collaboration between end-users and fuel suppliers to ensure optimal fuel selection and storage practices, vital for maintaining product reliability and sustainability. Proper evaluation of feedstock for HVO production is essential for accurately assessing its environmental impact.

While the Unified Interpretations to MARPOL Annex VI regulations provide a pathway for using B100 biofuels like HVO, vessel flag states’ adoption of these regulations is crucial for implementation.

To learn more about Biofuels and their role in marine operations, visit the Bergen Engines Future Fuels page.