| At Sea., Press Releases

Bergen, Norway – Bergen Engines proudly announces the sale of four Bergen C25:33L9A generating sets to Island Offshore Management, marking a significant milestone in the advancement of hybrid ocean energy construction vessels (OECVs). This innovative vessel, equipped with Bergen’s state-of-the-art technology, is set to revolutionize subsea operations and renewable energy projects.

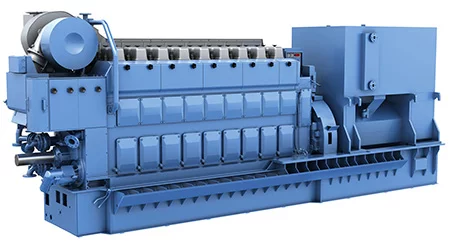

The Bergen C25:33L9A generating set is a cornerstone of this vessel’s capabilities, renowned for its unmatched reliability and performance. Its modularized design, featuring Bergen Engines’ signature Power Pack unit, streamlines maintenance with a cylinder head, liner, piston, and three-piece connecting rod. This innovative construction ensures optimal efficiency with Variable Valve Timing and maintains exceptional performance even under part-load conditions. Known for low emissions and cost-effectiveness, the C25:33L9 delivers a world-leading power-to-weight ratio, fast load response, and stable frequency, all while maintaining economical fuel and oil consumption.

Morten Ulstein, Chair of Island Offshore, expressed his confidence in the collaboration: “We are proud to present the next generation of hybrid OECVs with versatile capabilities that will ensure long-term employment as the energies of the ocean evolve. We strongly believe in the vessel concept and look forward to presenting the vessel to our clients.”

The new OECV, designed in collaboration between Island Offshore and VARD, is built for a multitude of subsea operations including inspection, maintenance, and repair (IMR), subsea infrastructure construction and installation, diving support, and remotely operated underwater inspection. Additionally, the vessel is equipped for renewable energy work scopes such as walk-to-work, commissioning, cable laying and repairs, trenching, and surveying.

With preparations for the installation of a gangway system and a heave compensated offshore subsea crane with a 250-ton capacity, the hybrid vessel is built for flexibility and versatility to meet the demands of various complex operations.

Designed for superior station-keeping, maneuverability, and sea-keeping abilities, the hull of the vessel is optimized for efficient operations. Importantly, the vessel is prepared for conversion to methanol operation to reduce emissions, aligning with Bergen Engines’ future solutions for low-emission fuel technology.

The vessel is of VARD 3-25 design. The hull will be constructed at VARD’s shipyard in Romania, with outfitting, commissioning, and delivery taking place at one of VARD’s shipyards in Norway. Delivery of the vessel is scheduled for Q1 2027.