From Power to Produce

Bergen Engines Delivers Maximum Efficiency for Marc Pittoors

Growing tomatoes requires a finely controlled environment where temperature, light, and CO2 levels must be precisely balanced for optimal yield and quality. To meet these stringent requirements while maximizing efficiency, Tuinbouwbedrijf Marc Pittoors (TBMP) turned to Bergen Engines’ state-of-the-art combined heat and power (CHP) system.

With an efficiency rate of over 96%, the medium-speed gas engines from Bergen Engines not only provide reliable electricity for artificial lighting but also recover heat from exhaust gases and cooling systems to warm the greenhouse. Additionally, CO2 extracted from the exhaust gas is reinjected into the greenhouse atmosphere, enhancing plant growth and productivity.

Cutting-Edge Technology for Maximum Output

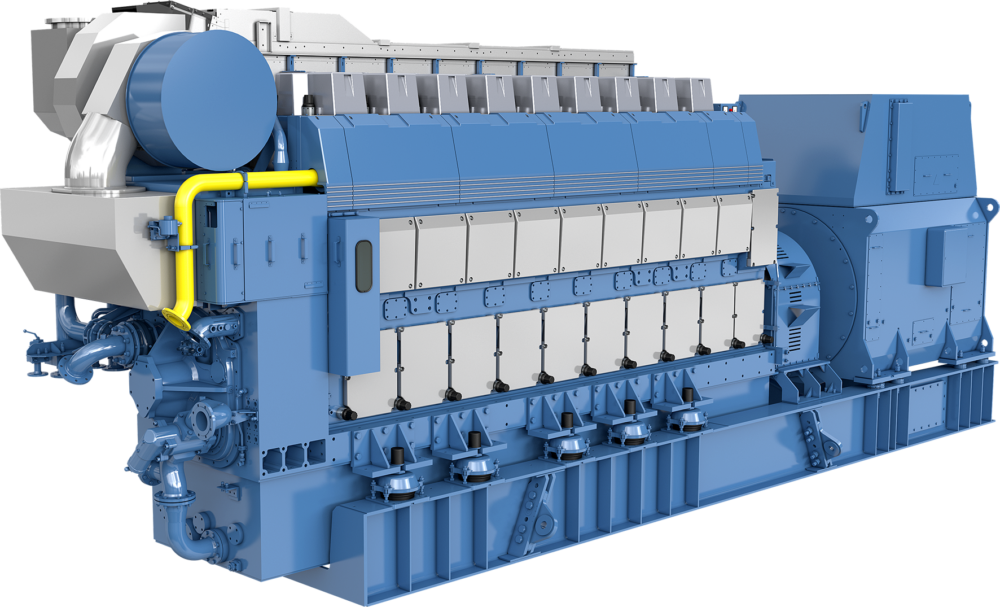

For its new greenhouse facility in Belgium, TBMP selected two six-cylinder B36:45 gas engines, known for their efficiency and low emissions. Our latest series of lean-burn gas engines delivers a 20% increase in power output compared to previous models while maintaining exceptional fuel efficiency.

Marc Pittoors, CEO of TBMP, highlighted the decisive factors behind their investment: “For our company, three factors were crucial in making this decision: best electrical efficiency in the market, Bergen Engines’ expertise in gas engines since the early 1990s, and optimal heat balance.”

Bergen Engines supplied the complete CHP system, including power generation sets, exhaust gas systems with selective catalytic reduction (SCR) units, heat exchangers, and an advanced electronic control system. The result is a highly efficient, self-sustaining greenhouse operation that minimizes energy waste while maximizing crop yields.

Key Facts

The Power of Decentralized Energy

Bergen Engines’ medium-speed gas engines play a key role in the shift toward decentralized energy production. Instead of relying on large, centralized power stations, businesses and industries are increasingly turning to on-site power generation solutions like CHP systems. This approach enhances energy security, reduces transmission losses, and allows facilities to operate independently from the grid when needed.

Natural gas-fired CHP plants also contribute to a cleaner energy future. Compared to traditional coal or oil-fired power generation, our technology significantly reduces greenhouse gas emissions, including NOx, CO2, and particulate matter. By combining heat, power, and CO2 enrichment, the TBMP greenhouse demonstrates how sustainable energy solutions can drive both economic and environmental benefits.

Long-Term Reliability & Support

Beyond delivering cutting-edge technology, Bergen Engines ensures long-term operational efficiency for the project through a 10-year Long Term Service Agreement (LTSA).

This agreement provides proactive maintenance, expert support, and performance optimization, ensuring that the TBMP greenhouse continues to operate at peak efficiency for years to come.

A Model for the Future of Greenhouse Energy

The success of TBMP’s CHP plant highlights the immense potential of Bergen Engines’ medium-speed gas technology for the agricultural sector. With the ability to deliver stable, efficient, and environmentally friendly energy solutions, Bergen Engines is setting a new standard for greenhouse operations worldwide.

B36:45L9

Bergen’s B36:45 gas engine stands as a testament to innovation. Purpose-built for land-based applications, this inline medium-speed lean-burn unit generates up to 6MW of mechanical power. Equipped with state-of-the-art combustion technology, it ensures optimal efficiency and unparalleled load responsiveness.

- Power Range: 3.4 – 5.3MW

- Up to 48% efficiency

- Low lifecycle costs

Contact us

Please fill in your contact details below and we’ll reply as soon as we’re able.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request