Operator Training

In the realm of engine operation, the key to long-term success lies in having highly qualified operators. Their proactive service from day one can significantly enhance availability and safety. When engines are diligently maintained by skilled personnel, they not only perform optimally but also demonstrate enhanced reliability, mitigating the risks of breakdowns and compromised performance.

Investing in operator training and authentic spare parts stands as the ultimate safeguard for your equipment’s longevity and productivity. With Bergen Engines, your operators receive comprehensive training from qualified instructors, equipping them with the knowledge to optimize equipment performance and availability.

SCROLL TO EXPLORE

Empowering Your Operators for Optimal Performance

Understanding Systems and Processes

Bergen Engines’ operator training programs are meticulously crafted to provide operators with a deep understanding of systems and processes. This knowledge empowers them to identify root causes, anticipate consequences, and react proactively to any deviations, thereby ensuring uninterrupted operations.

Analytical Skills for Proactive Maintenance

Professionally trained operators possess invaluable analytical skills. From deciphering error codes to identifying trends and potential failures, they play a pivotal role in maintaining equipment at its peak performance. With their expertise, downtime is minimized to planned maintenance events, keeping operations running smoothly.

DID YOU KNOW?

Realizing the Benefits of Skilled Operators

Enhanced Reliability and Efficiency

Skilled operators directly translate to enhanced reliability and efficiency of your equipment. By minimizing the risk of outages due to poor maintenance or lack of system knowledge, they optimize availability and performance, ensuring seamless operations.

Reduced Costs and Improved Safety

Investing in operator training not only reduces the usage of spare parts and unplanned service activities but also facilitates maintenance planning and contingency stock management. Moreover, it improves plant safety, creating a conducive work environment for all.

Chapter 4: The Training Journey with Bergen Engines

Tailored Learning Experience

At Bergen Engines, we understand that every operator and situation is unique. That’s why our training programs are customized based on equipment and operator skill level, ensuring a tailored learning experience for maximum efficacy. Our courses cover a wide array of topics that are essential for efficient operation and maintenance, gaining hands-on experience and theoretical knowledge crucial for daily tasks.

Typical course content includes

- Routine Maintenance Scheduling (RMS)

- Design, function and operational mode of main components

- Fuel Injection equipment (gas/liquid)

- Automation and Control System

- Engine Instrumentation

- Safety Systems

- Start, Ramp-Up, Stop and Operation

- Lube Oil, Fuel and Cooling Water Quality

- Utilization of Testing Equipment and Special Tools

- & More!

Certification and Support

Upon successful completion of our courses, operators receive certification and ongoing support from Bergen Engines. We are committed to the continuous growth and development of your team, ensuring they remain at the forefront of operational excellence.

Enabling Success Through Training Investment

Embark on the journey of excellence with Bergen Engines. Our introductory training sets the foundation, while refresher courses ensure continuous improvement. With each session, operators refine their skills, becoming proficient in maintaining and operating equipment safely and effectively. The course fee covers all essentials, including documentation, a daily lunch, transportation (if in Bergen), and personal protective equipment. With Bergen Engines, investing in operator training is not just an expense but a strategic investment in the long-term success of your operations.

Learn more by downloading our Operator Training brochure below:

Other Services

Swipe to see all services

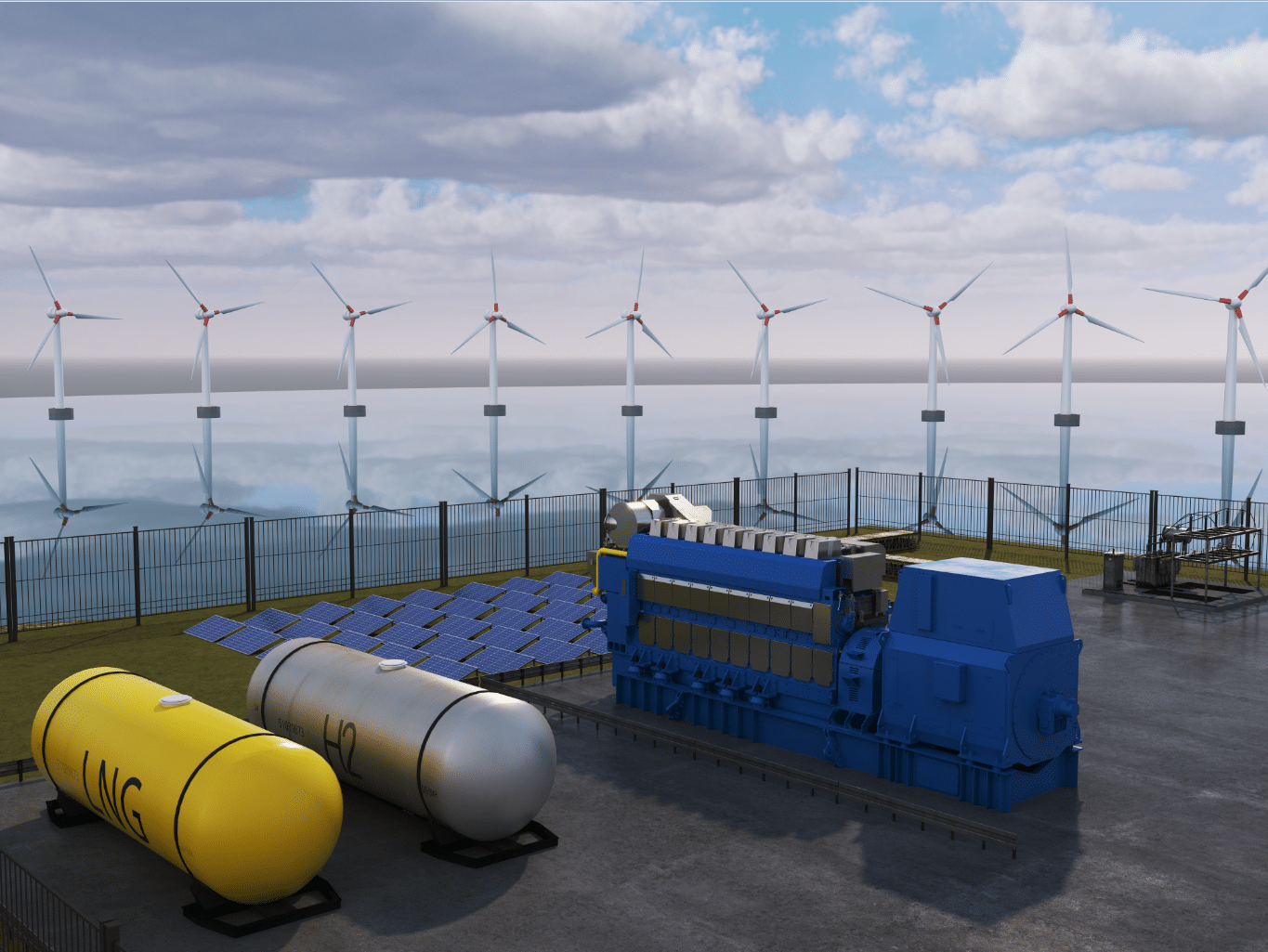

ON LAND.

Bergen engines are principally found driving alternators in power generation applications, either singularly or in multiples up to 200MW, with 300MW currently under construction. Our engines and generator sets are widely recognised by operators worldwide due to their proven technology, robust design, and low operating costs.

AT SEA.

Bergen engines power generators for offshore oil & gas installations and on board a wide range of ocean-going vessels. Bergen engines can also be found in direct propulsion applications. From tugs and fishing vessels, to ferries, offshore supply and cruise ships, Bergen engines are a watchword for supreme quality and reliability in the marine industry.

Contact us

Please fill in your contact details below and we’ll reply as soon as we’re able.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request