Helsinge Fjernvarme

By delivering both heat and electricity to the community and contributing to the national grid, Helsinge Fjernvarme sets a precedent for sustainable and community-focused energy production. This case study highlights the engine’s superior performance and the positive impact on local energy costs and environmental sustainability.

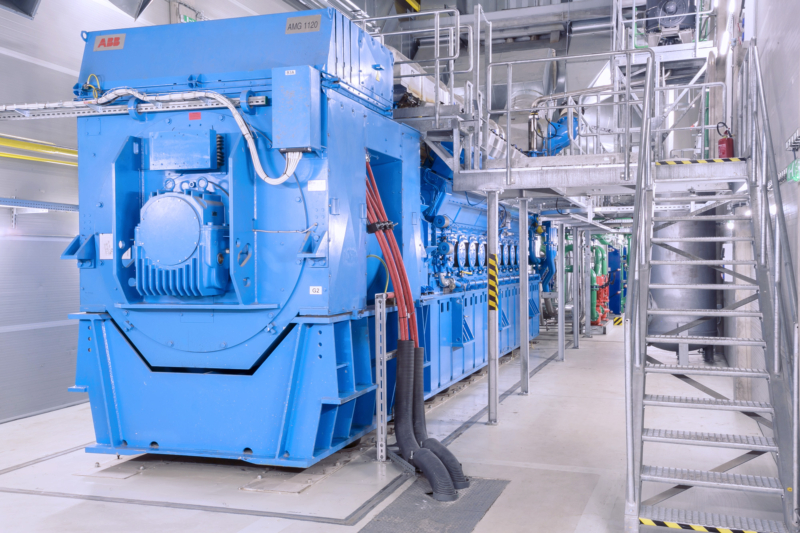

Project Overview: The installation of the 20-cylinder B35:40V20AG lean-burn unit in Helsinge, north of Copenhagen, marked a significant milestone as the first 20-cylinder plant of its kind to become fully operational. This case study explores how Helsinge Fjernvarme leveraged Bergen Engines’ advanced technology to deliver reliable and efficient heat and electricity to the local community.

Technological Implementation:

- Engine Specifications: The plant features a B35:40V20AG natural gas engine, delivering 8,500 kWe of electrical power and 9,510 kWt of thermal power.

Strategic Importance: Operating in combined heat and power (CHP) mode, the power plant provides heat to 1,400 local homes, with excess electricity sold to the national grid. This dual-functionality enhances energy efficiency and supports the local economy by reducing heating costs.

Operational Execution: The B35:40V20AG engine, an extension of the popular K-gas series, was selected for its high efficiency, low exhaust emissions, and reliability. Despite also being available in 12 and 16-cylinder versions, the largest 20-cylinder format was chosen to meet Helsinge’s energy needs. The engine became operational in 2006, achieving measured efficiency figures of 45.5% (47.7% according to ISO 3046-1), surpassing the guaranteed efficiency by 1.3%.

Key Features:

- Efficiency: High electrical and heat recovery efficiency.

- Environmental Impact: Designed to lower exhaust emissions.

- Operational Flexibility: Capable of adjusting operation based on electricity prices, which are monitored hourly.

Community Impact:

The non-profit nature of the Helsinge plant ensures that excess electricity profits are used to reduce heating costs for local residents. The sleek, modern exterior of the power station complements its advanced internal technology, symbolizing a commitment to sustainability and community welfare.

Support Systems: The power station retains two original 18-cylinder K-gas engines, each with a mechanical output of 3.06 MW, for standby duty. The 20-cylinder engine operates primarily when electricity prices are favorable, often being turned on and off up to three times daily to maximize economic efficiency. This operational demand highlights the engine’s robust quality and reliability.

Contact us

Please fill in your contact details below and we’ll reply as soon as we’re able.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request