History

EXPLORE TO SCROLL

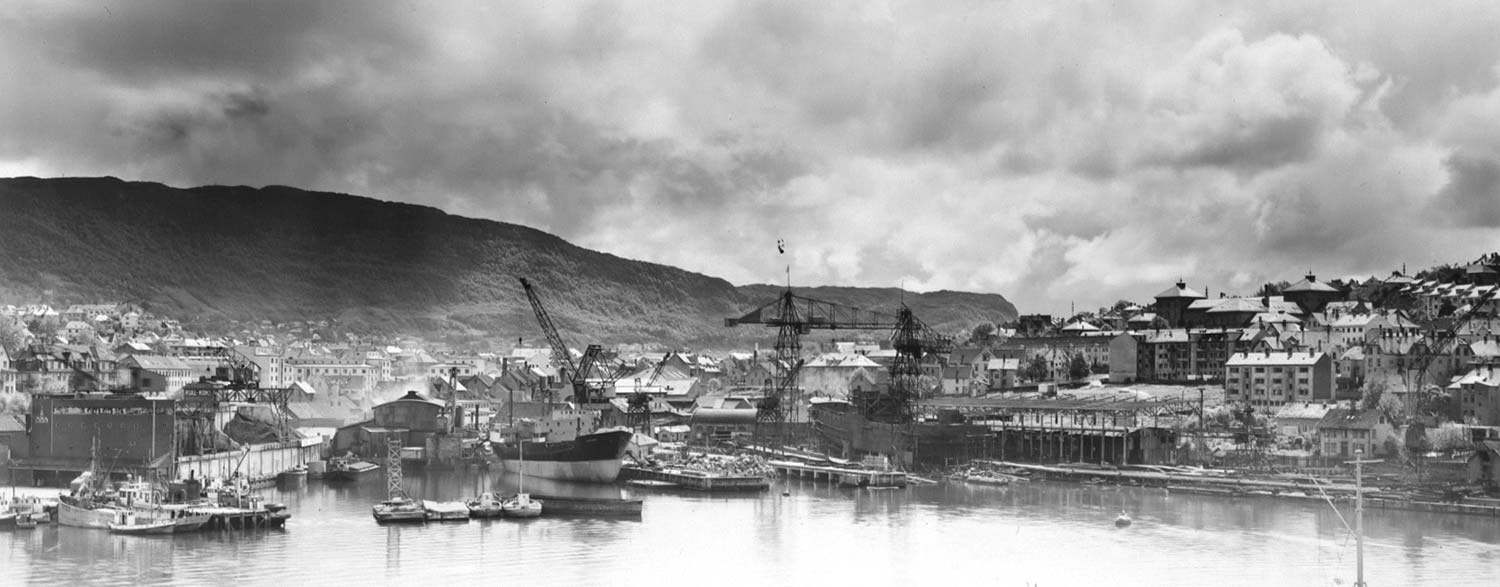

Established as a pure engine manufacturer in 1943, Bergen Engines delivered its first engine in 1946. The company built a new factory in 1971 at Hordvikneset, north of Bergen, and became a Rolls-Royce company in 1999.

In 2021, Bergen Engines was acquired by Langley Holdings with the sale finalised on December 31, 2021.

Until 1946, the Bergen engines were produced by the shipyard BMV (Bergen Mekaniske Verksted). BMV had been purchasing engines from sub-suppliers for many years, but were not satisfied with the low reliability of these engines, so BMV decided to develop their own, high quality engines, that were perfectly adapted to the harsh environment of the Atlantic Sea.

Timeline

About

Bergen Engines AS builds iconic medium-speed liquid fuelled and gas fuelled reciprocating engines for marine and land based applications.

Our engines can be found operating in some of the most demanding and hostile environments on earth, both on land and at sea.

Our Facilities

Every Bergen engine built is manufactured at our factory in Hordvikneset, near Bergen, in Norway. Our well-invested facilities are situated on a 23 hectares (50 acres) freehold site and extend to over 20,000 square metres (2,000,000 square feet) of production and office accommodation.

Contact us

Please fill in your contact details below and we’ll reply as soon as we’re able.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request